These products are developed from extra heavy gauge steel tubes and zinc plating to ensure they are both durable and aesthetically attractive. Each trampoline’s coverall frame pads are made from lightweight foam and covered in nylon-reinforced PVC for enhanced safety and improved comfort.

We’re one of the leading trampoline suppliers in the UK, largely because we take great care throughout the entire process to ensure high quality results, every time. Here’s how we create and distribute these hard-wearing trampolines for our customers.

The different sections of steel tube – some round, oval and square – are taken out of the storage rack and cut to length ready for bending. The end rails and leg sections are then bent to the required angles on our bespoke bending machine, using different formers. Once this step is complete, the parts are stored ready for the next part of the manufacturing process.

Bending the frame

Completed frames ready for next step

Numerous trampoline parts are turned, drilled, and deburred. These components are put in various jigs prior to welding to make up the several different completed trampoline sections. Many of these sections are universal across our range of trampoline sizes.

Lath

Welding

Completed and welded components and sections

Completed and welded components and sections

The completed sections are loaded onto stillages to be sent to be bright zinc plated and then stored in our warehouse once completed. From here, they will be ready for assembly in batches.

Before plating

After plating

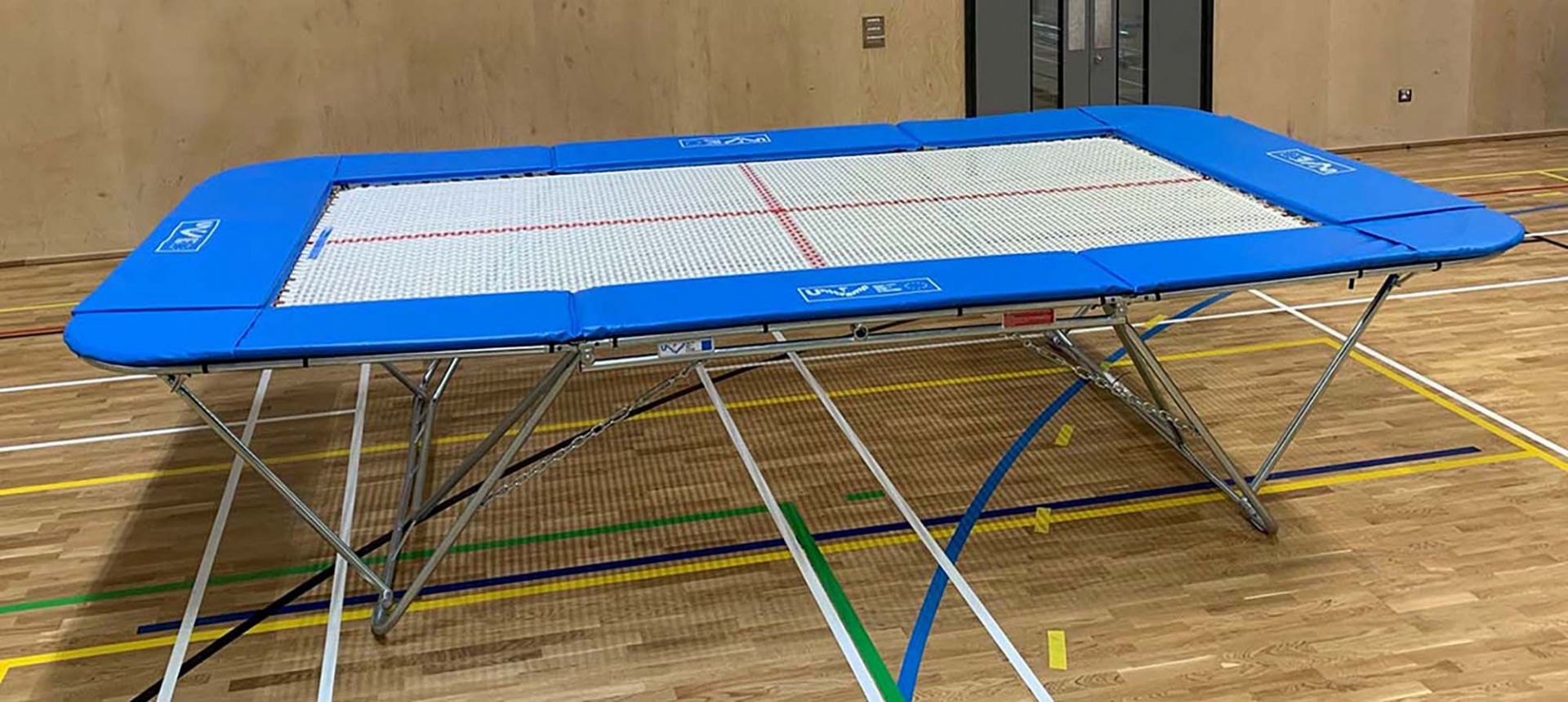

The various sized trampoline frames are assembled and stored ready to be fitted with the relevant sized trampoline web bed, along with the trampoline coverall pads and our standard, lift/lower or dampened lift/lower rollerstands.

Once the trampoline is completely built, it is checked prior to loading onto our own delivery vehicles.

In store area before bedding

On vehicle for delivery

The trampoline is delivered to the customer and left in their hall. Staff can then set up the trampoline as required, with no need for reassembly.

You can also view our full range of trampolines here, plus our excellent selection of spotting decks, mats, spares, and other accessories.

RELATED ARTICLES - buying guides manufacturing

Published on 14 February 2024 By Andreas Fantousi

CALL THE SALES TEAM ON +44 (0)1621 868 700

Or send your enquiry