To add a different dimension to our portfolio, we also produce the majority of our timber products ourselves, including best-sellers like cricket creels, vaulting boxes, and PE benches for schools.

Here, we’ve outlined the various processes involved in the manufacturing of these wooden products.

We use all kinds of timber, and the exact material will depend on the item that’s being created. You can rest assured, however, that all the timber used is FSC certified, which means it has been sourced from responsibly managed forests and meets the highest environmental standards.

The different sections of timber are taken out of the storage rack and cut to the correct length and size. Then, using a six cutter, the timber is finished on all four sides, whilst simultaneously forming any radiuses or chamfers to suit the product’s requirements.

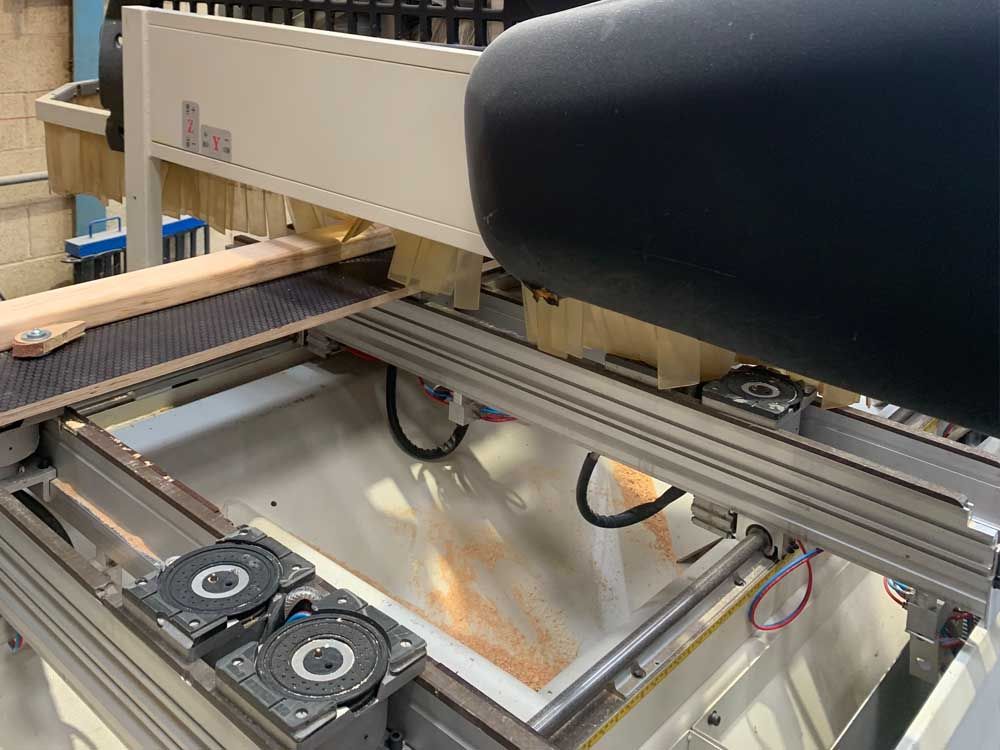

Numerous components like bench feet, vaulting box sides and cricket creel ends are put in the appropriate jig prior to processing on a CNC machine. This equipment selects the appropriate cutting tools that we will need to form the different profiles and shapes required for the build, resulting in an accurately shaped component.

CNC Machine

Completed Components

Completed Components

The completed CNC sections are then sanded through a speed sander which completes both a course and fine sanding of flat surfaces in one single operation.

The various sized PE benches and vaulting boxes are put together and checked over by our staff.

Vault Assembly

Vault Assembly

Bench Assembly

The completed products are lacquered in our wetback spray bay, ready for final assembly. These are wrapped and put into storage, ready to be despatched as and when orders come in.

Lacquering

Lacquering

Final Assembly

Final Assembly

Vault Wrapped & Stored

Benches Boxed Up

RELATED ARTICLES - manufacturing

Published on 18 June 2024 By Andreas Fantousi

CALL THE SALES TEAM ON +44 (0)1621 868 700

Or send your enquiry