Every product is carefully crafted at our very own factory in Maldon, Essex, ensuring we can keep a close eye on the quality and consistency of these items, and they are all thoroughly tested for durability, strength, and, of course, safety considerations.

Our frames offer a huge range of options to PE teachers, helping them keep their lessons varied and engaging. Each of these versatile climbing frames can be adapted to support everything from simple rung climbing exercises to developing children’s problem-solving abilities by asking them to manoeuvre through, on, over and under a variety of objects. The swivel rings can be set at different angles to create a more challenging setup along with using linking equipment to further enhance the frames flexibility. One thing’s for sure – kids will never get bored when this apparatus is involved!

As well as using this climbing frame equipment to promote and improve their pupils’ PE skills, teachers can use these products to develop confidence, risk taking and teamwork skills, all of which are vital both inside and outside the school environment.

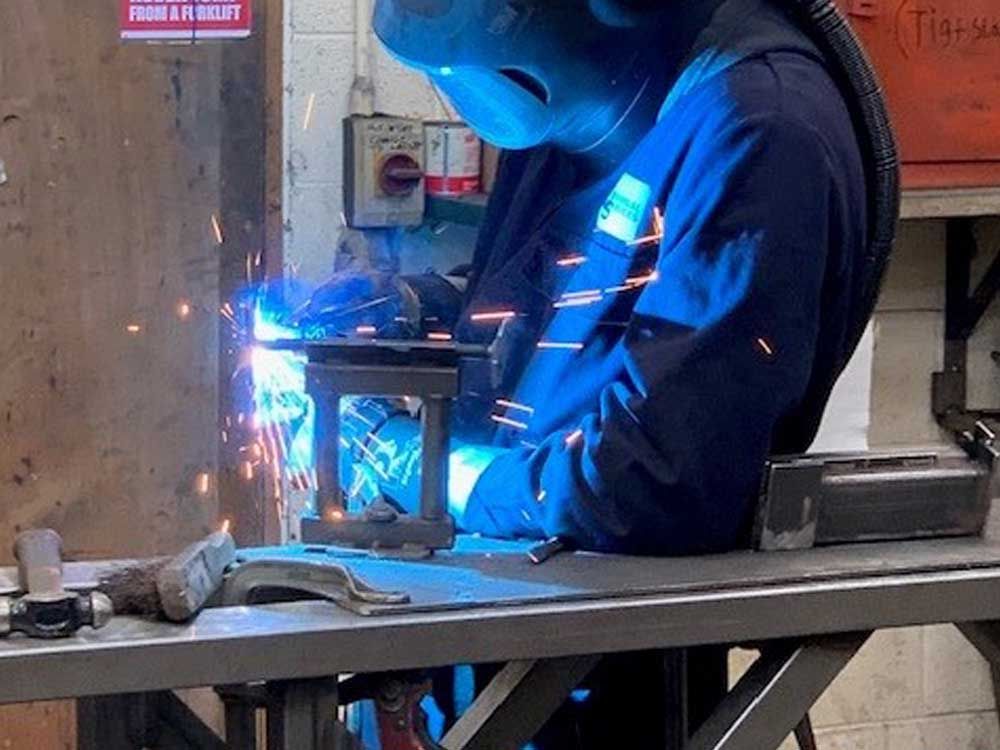

Ever wondered how we bring our climbing frames to life? Below, we talk you through exactly how the frames are designed, delivered, assembled and installed onsite by our in-house engineering team.

The various sections of steel tubing are taken out of the storage rack and cut to size for welding, punching, and painting. Tubes can be flat or square. Once this part of the process is complete, the parts will be stored ready for despatch.

The timber components are cut to length, then put in a jig and through the CNC machine prior to being sanded. The parts are lacquered prior to either being partially assembled (in the case of our box ladder and double incline ladder) or just stored (in the case of our main frame timber uprights) ready for despatch.

The aluminium tube sections that make up the main climbing frame are cut to size and stored ready for despatch.

The various components for the frames are taken to site by our installation team and then assembled in the hall before the frame is mounted on the chosen wall.

And voila! After a few standard safety checks and talking the teacher and their assistants through how to operate and resecure the equipment, the climbing frame is ready to be used.

The climbing frames in our range are available to cover the requirements of all younger school age children, from early years through to Key Stage 4. Our Trio climbing frame is a firm customer favourite thanks to its familiar, brightly coloured aesthetic, while our Trio Nova and Super Nova frames have been designed after years of research and development to create best-in-class equipment that is hard-wearing and slightly more challenging for their users.

RELATED ARTICLES - manufacturing

Published on 28 May 2024 By Andreas Fantousi

CALL THE SALES TEAM ON +44 (0)1621 868 700

Or send your enquiry